SYI Equipment is your best choice!

SYI Equipment is your best choice!

– Excellent Quality

– On time Delivery

– Competitive Price

.

SYI Equipment Division ( a Proud Member of SYI Group ) – manufactures inverter industrial electric heating equipment and industrial micro control units.

The main products are KGPS Series Thyristors Medium Frequency Power Source, GW Series Medium Frequency Induction Coreless Melting Furnace, GT Series Medium Frequency induction Diathermanous Equipment and BCT Series Closed Type Cooling Tower. These products cover 4 series and 40 plus models. They are widely used in many industry fields such as metallurgy, machinery and construction materials etc.

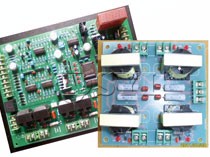

KGPS Series Thyristors Medium Frequency Power Source

KGPS Series Thyristors Medium Frequency Power Source is the product through many years of absorbing foreign advanced technology, based on customers’ actual needs and having been innovated continuously to date.The inverter circuit of our brand new KGPS Medium Frequency Power Source Cabinet consists of 16 of silicon controlled units, hence users’ maintenance cost is lowered and efficiency is increased. >> Application This is mainly used as the medium frequency power source for induction melting, heat preservation, diathermia and quenching. >> Characteristics – Completely intergrated circuits constant rated power control panel; – Hihg-performance control guaranteeing you successful start-up with one single try in any circumstances and then with aoutomatic adjustment; – High reliability, simplified operation and easy maintenance; – High-efficiency-and-low-consumption conversion between electricity and heat meaning an up to 30% power save in your melting. Main models and parameters of KGPS Series Thyristors Medium Frequency Power Source

|

.

GW Series Medium Frequency Induction Coreless Melting Furnace

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Model | Rated Melting Amount (T) | Rated Power (Kw) | Rated Frequency (KHZ) | Rated Operational Voltage(V) | Iron Melting | Steel Melting | ||

| Power Consumption (Kw.h/t) | Melting Power (t/h) | Power Consumption (Kw.h/t) | Melting Power (t/h) | |||||

| GW0.25-160-1 | 0.25 | 160 | 1 | 800 | 1150 | 0.220 | 880 | 0.30 |

| GW0.5-250-1 | 0.50 | 400 | 1 | 800 | 1100 | 0.380 | 850 | 0.40 |

| GW0.75-350-1 | 0.75 | 500 | 1 | 800 | 1020 | 0.500 | 800 | 0.80 |

| GW1-500-1 | 1.00 | 630 | 1 | 850/1200 | 950 | 0.850 | 750 | 1.10 |

| GW1.5-750-1 | 1.50 | 800 | 1 | 850/1200 | 900 | 1.000 | 730 | 1.30 |

| GW2-1000-1 | 2.00 | 1000 | 1 | 1200 | 850 | 1.300 | 720 | 1.60 |

| GW2.5-1250-0.5 | 2.50 | 1250 | 0.5 | 1200 | 800 | 2.500 | 700 | 2.30 |

| GW3-1500-0.5 | 3.00 | 1500 | 0.5 | 1400 | 780 | 2.700 | 650 | 2.80 |

| GW5-2000-0.5 | 5.00 | 2000 | 0.5 | 1400 | 750 | 3.800 | 610 | 4.20 |

Various induction heating coil Frequency transformer

Frequency transformer Electric Capacitor

Electric Capacitor Various electric reactor winding

Various electric reactor winding Rubber hose

Rubber hose Control panel

Control panel Asbestos-board

Asbestos-board Various reducer components

Various reducer components Thyristor

Thyristor Various thyristor radiator

Various thyristor radiator Speed reducer

Speed reducer Various insulation materials

Various insulation materials Various magnetic rings and cores

Various magnetic rings and cores Hydraulic pressure station

Hydraulic pressure station Electric reactor

Electric reactor Various joints

Various joints

.

GT Series Medium Frequency induction Diathermanous Equipment>> Application It is mainly used to heat the metallic materials up before forging, extruding and hot rolling, and used to do some heat treatments. >> Charateristics – It is designed in an electro-mechanically integrated structure and occupies less area, so it is convenient for use in mechanization and automation production line. – It is with high heating speed, low decarbonization, high efficiency and good process repeatability. – There are many models of heating inductors and all highly efficient; the refractory lining is with long life span and replacing process is simple. – The working environment is good, pollution is low and labor intensity is low.

|

.

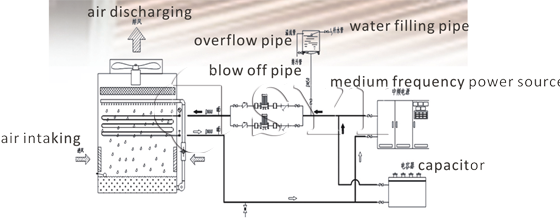

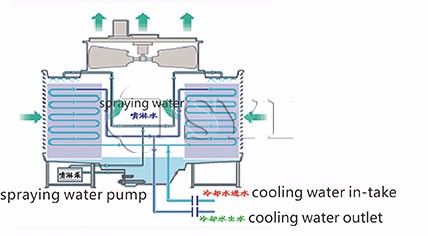

BCT Series Closed Type Cooling TowerThe closed type cooling tower consists of the mainframe, expansion tank, circulating pump and electric control cabinet. The mainframe consists of housing, heat exchanger, draught fan, spraying system, water tank and pipe line valves etc.

The heat carrying medium (cooling water, oil or other liquid) is driven by the system’s circulating pump and flowing in the coiler then through to the equipment to be cooled (such as power source, furnace body etc). The closed type cooling tower has two operating models, one is air cooling, and the other is air + spraying water cooling. Two models are switched between each other automaticly by the electric control system based on the working conditions and so that energy saving is realized.

>> Characteristics – Cooling medium is in a completely closed circulation so impurities are prevented from entering into the system and medium is prevented from evaporating. >> Application scope – To do the cooling for cold induction heating equipment and metal melting equipment, such as high/medium frequency quenching equipment, medium frequency power source and electric furnace, induction diathermanous furnace and holding furnace. |

Closed type cooling tower’s advantages compared to other heat-extraction system

* In comparison with air cooling system: Process temperature is lowered by 10-20 ℃, space needed is smaller and energy consumption is lower.

* In comparison with air cooling system: Process temperature is lowered by 10-20 ℃, space needed is smaller and energy consumption is lower.

* In comparison with disposable water cooling system: Environmental harm is reduced and energy saving could be up to 95%.

* In comparison with cooling tower + heat exchanger system: The temperature is closer to that of the air, and scaling is reduced and efficiency is increased.

* In comparison with open type cooling tower: As the closed type could be rid of potential contamination, the scaling during the process is largely redued and constant process quality could maintain in a long term operation.